The daily camera van *Work in progress 151122*

This is a work in progress but as the blog is being written at the same time as I am working (for a change), I thought I might as well publish it to make it a live update of sorts. So do pop back in the future to see when I finally give up and set the lot on fire.

"When you reverse things tend to come from behind ya'." is a quote to remember when driving a near 5 metre long van.

Funnily enough I took to reversing this thing without too much trouble but I could see myself hitting some issues or walls if I was at a funny angle...

A reversing camera or sensors was the answer. I liked the camera on my T5 so fancied doing something similar on the Daily. Unfortunately my single Din headunit did not provide a suitable screen to display this image so I needed to add a screen somewhere too. To the interwebs to find the answer!

There are lots of different reversing cameras out there with optional lights or even IR. I would like to 1080p for better image quality (they are that cheap now its silly not to) so finding one wouldn't be hard. Finding a discreet screen to display the rear-view camera was going to be the biggest challenge though. I am not a fan of dashboard clutter and a lot of the screens on offer looked clumsy even in their adverts.

I shopped about a bit and settled on a combo where the display was hidden inside a rear view mirror with an included reversing camera and a bonus dash cam. The whole thing was 1080p HD quality, pretty compact and cheap at £29.

There are lots of different reversing cameras out there with optional lights or even IR. I would like to 1080p for better image quality (they are that cheap now its silly not to) so finding one wouldn't be hard. Finding a discreet screen to display the rear-view camera was going to be the biggest challenge though. I am not a fan of dashboard clutter and a lot of the screens on offer looked clumsy even in their adverts.

I shopped about a bit and settled on a combo where the display was hidden inside a rear view mirror with an included reversing camera and a bonus dash cam. The whole thing was 1080p HD quality, pretty compact and cheap at £29.

If you want the whole story, read along. If you want to cut to the facts, skip all of the italics.

Much to my surprise it actually fit the van just fine. The rails needed a bit of a tidy up and trim with a craft knife where I had not had internal supports on (silly me) but as you can see it fits in nicely with a firm push it is tight enough to not fall out.

all that was left now was to put some sticky back foam on the back of the mirror and stick it on.

Wiring

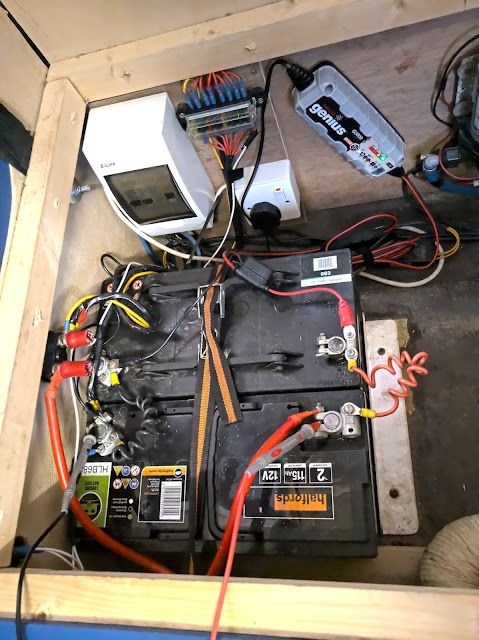

When the kit arrived it has two sets of wiring. One for the power and the other for the rear camera. Both are simple plug in jobs so nothing wild here. I did not want to use a cigarette lighter for power though so would have to get creative.

I decided to chop up the power plug and solder some wires with crimped bullet terminals then find a redundant wire in the van and tap into its power supply. Once I found one in a suitable place under the dash I crimped on some connectors to those wires and ran the power lead through the dash and up the A1 pillar, over the headlining and dropped it down near the mirror base plate ready to use.

This worked okay but, much like a cigarette lighter socket, it just sits there draining the battery so I ended up replacing this with a piggyback fuse hard wire kit.

The reversing camera wiring (for the camera in the kit) is just plug and play with a single power wire for the lights. This needs to be extended to the light cluster where it can pick up the reverse light power line.

Bracket

The first headache was getting the mirror fitted as I have no rearview mirror. It would be kind of pointless unless you like looking at the rear bulkhead.

I contemplated a few options including just buying a rear view mirror and fitting it as intended but that would be too easy.

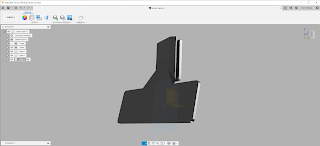

As I have the mounting plate for a rear view mirror on the windscreen I decided to design my own bracket in fusion 360 so it would fit in as per the OEM mirror then 3D print it with my Copymaster 3D 300.

I had a list of measurements taken from the go-pro like base plate so I could design the rails to just slot in. I then blended a short arm into that to a wide base plate which I tilted slightly for a more comfortable viewing angle. Surprisingly this only took me a morning as a complete 3D design newby.

The end result was then exported as an .STL file and opened in Cura.

The end result was then exported as an .STL file and opened in Cura.

Due to its shape I had to print with supports and increased wall thickness to 3 layers for added strength. I only had PLA to hand at the time but for winter that should be fine. It is very hard and resilient material but when things get warm I know it will deform. This was the first try so I didn't really expect it to fit at all.

Once the print was set up I stuck it in the 3D printer whilst I had my lunch. an hour or so later I had the finished product. I cut the supports away leaving the tiny little bracket ready to fit.

I contemplated a few options including just buying a rear view mirror and fitting it as intended but that would be too easy.

|

| Looking super shiny as a render. |

I had a list of measurements taken from the go-pro like base plate so I could design the rails to just slot in. I then blended a short arm into that to a wide base plate which I tilted slightly for a more comfortable viewing angle. Surprisingly this only took me a morning as a complete 3D design newby.

The end result was then exported as an .STL file and opened in Cura.

The end result was then exported as an .STL file and opened in Cura.Due to its shape I had to print with supports and increased wall thickness to 3 layers for added strength. I only had PLA to hand at the time but for winter that should be fine. It is very hard and resilient material but when things get warm I know it will deform. This was the first try so I didn't really expect it to fit at all.

Once the print was set up I stuck it in the 3D printer whilst I had my lunch. an hour or so later I had the finished product. I cut the supports away leaving the tiny little bracket ready to fit.

Much to my surprise it actually fit the van just fine. The rails needed a bit of a tidy up and trim with a craft knife where I had not had internal supports on (silly me) but as you can see it fits in nicely with a firm push it is tight enough to not fall out.

all that was left now was to put some sticky back foam on the back of the mirror and stick it on.

The only part of the mirror design I had not measured was the angle of the mirror plate which I had made too flat to the windscreen for me.

This means that the right corner of the mirror touches the windscreen which not only rattles but also adds enough pressure to slowly peal the mirror from the bracket. The other down side to this is that the camera points too high to record anything of real interest unless you are into twitching. Not bad for a first try though!

The unit works fine like this and a road test proved it to be okay even if the foam tape let go on the bracket so some screws might be a better idea as at least a backup.

It wasn't long before I was back in front of the computer redesigning the bracket. I was also armed with a fresh roll of PET-G filament. This stuff is far more resilient to heat than PLA so, without going to ABS, this aught to be the finished items filament of choice. I had a bit of a faf getting it setup but that was mostly my own fault.

It wasn't long before I was back in front of the computer redesigning the bracket. I was also armed with a fresh roll of PET-G filament. This stuff is far more resilient to heat than PLA so, without going to ABS, this aught to be the finished items filament of choice. I had a bit of a faf getting it setup but that was mostly my own fault.

The revised version 2 design has a much more angled mirror plate and is off set away from the windscreen so that the top of the mirror does not impact the base plate or the windscreen. This redesign worked however i had to offset the bracket from the centre of the mirror to avoid the top socket bar which is slightly protruding on the mirror. I used adhesive foam tape again for attaching. This was backed up by two very short self tapping screws which I piloted with a 1.5mm drill bit. The screws are short enough to miss the underlying pcb whilst further securing the mirror to the plate. The end result looks great from the drivers perspective.

The revised version 2 design has a much more angled mirror plate and is off set away from the windscreen so that the top of the mirror does not impact the base plate or the windscreen. This redesign worked however i had to offset the bracket from the centre of the mirror to avoid the top socket bar which is slightly protruding on the mirror. I used adhesive foam tape again for attaching. This was backed up by two very short self tapping screws which I piloted with a 1.5mm drill bit. The screws are short enough to miss the underlying pcb whilst further securing the mirror to the plate. The end result looks great from the drivers perspective.

I am really happy with the finish of the PET-G too which was being used for the first time.

I am really happy with the finish of the PET-G too which was being used for the first time.

Back in front of the computer, I had a few bits to tidy up:

Obviously I started this with a new logo design. You might have noticed the logo on the last two brackets; well I had always intended to offer these for sale once they were done so a bit of branding would be needed. Heggs Performance Tuning became Heggs performance Engineering as I thought it would be more suitable and a logo was drawn up on Photoshop.

Obviously I started this with a new logo design. You might have noticed the logo on the last two brackets; well I had always intended to offer these for sale once they were done so a bit of branding would be needed. Heggs Performance Tuning became Heggs performance Engineering as I thought it would be more suitable and a logo was drawn up on Photoshop.

I will use this logo on any future products I end up making and now have a Facebook page as well as its own blog to share it all.

The arm design had no more give in it for me to make it fit the way I wanted so I deleted it and started again.

The new design was created in a more organic way and after a few attempts came out nicely.

I then gave the base plate a small trim to remove its over hang and reduce the width of the rails by 0.2mm to stop them binding when fitting. The mirror plate got the 5mm scoot it needed then I was done with a finished Version 3 bracket. Could this be it?

The answer was no. Although this did work, it has no adjustment and after a warm summer, the sticky foam pad letgo and the mirror got shelved.

This means that the right corner of the mirror touches the windscreen which not only rattles but also adds enough pressure to slowly peal the mirror from the bracket. The other down side to this is that the camera points too high to record anything of real interest unless you are into twitching. Not bad for a first try though!

The unit works fine like this and a road test proved it to be okay even if the foam tape let go on the bracket so some screws might be a better idea as at least a backup.

It wasn't long before I was back in front of the computer redesigning the bracket. I was also armed with a fresh roll of PET-G filament. This stuff is far more resilient to heat than PLA so, without going to ABS, this aught to be the finished items filament of choice. I had a bit of a faf getting it setup but that was mostly my own fault.

It wasn't long before I was back in front of the computer redesigning the bracket. I was also armed with a fresh roll of PET-G filament. This stuff is far more resilient to heat than PLA so, without going to ABS, this aught to be the finished items filament of choice. I had a bit of a faf getting it setup but that was mostly my own fault. The revised version 2 design has a much more angled mirror plate and is off set away from the windscreen so that the top of the mirror does not impact the base plate or the windscreen. This redesign worked however i had to offset the bracket from the centre of the mirror to avoid the top socket bar which is slightly protruding on the mirror. I used adhesive foam tape again for attaching. This was backed up by two very short self tapping screws which I piloted with a 1.5mm drill bit. The screws are short enough to miss the underlying pcb whilst further securing the mirror to the plate. The end result looks great from the drivers perspective.

The revised version 2 design has a much more angled mirror plate and is off set away from the windscreen so that the top of the mirror does not impact the base plate or the windscreen. This redesign worked however i had to offset the bracket from the centre of the mirror to avoid the top socket bar which is slightly protruding on the mirror. I used adhesive foam tape again for attaching. This was backed up by two very short self tapping screws which I piloted with a 1.5mm drill bit. The screws are short enough to miss the underlying pcb whilst further securing the mirror to the plate. The end result looks great from the drivers perspective.  I am really happy with the finish of the PET-G too which was being used for the first time.

I am really happy with the finish of the PET-G too which was being used for the first time.Back in front of the computer, I had a few bits to tidy up:

- I don't like the way the arm joins the mirror plate.

- The base plate it too long.

- The mirror plate needs to scoot to the left a bit.

Obviously I started this with a new logo design. You might have noticed the logo on the last two brackets; well I had always intended to offer these for sale once they were done so a bit of branding would be needed. Heggs Performance Tuning became Heggs performance Engineering as I thought it would be more suitable and a logo was drawn up on Photoshop.

Obviously I started this with a new logo design. You might have noticed the logo on the last two brackets; well I had always intended to offer these for sale once they were done so a bit of branding would be needed. Heggs Performance Tuning became Heggs performance Engineering as I thought it would be more suitable and a logo was drawn up on Photoshop.I will use this logo on any future products I end up making and now have a Facebook page as well as its own blog to share it all.

The arm design had no more give in it for me to make it fit the way I wanted so I deleted it and started again.

The new design was created in a more organic way and after a few attempts came out nicely.

I then gave the base plate a small trim to remove its over hang and reduce the width of the rails by 0.2mm to stop them binding when fitting. The mirror plate got the 5mm scoot it needed then I was done with a finished Version 3 bracket. Could this be it?

The answer was no. Although this did work, it has no adjustment and after a warm summer, the sticky foam pad letgo and the mirror got shelved.

Getting into the winter of 2022 now I was getting a bit fed up of trying ton to damage this mirror sat on my garage shelf so I decided to sort it out.

I decided to start from the beginning for what must be the fourth time now, quickly drawing up a base plate then...

Well I had printed a gimbal before and it worked surprisingly well but I decided to extend the usability of the item and make my life a whole lot easier by using action camera brackets like those used on GoPro cameras. A female adapter was modelled onto the mount, I then hade a male adapter drawn up and grafted to a base plate for the mirror side. All I then needed to do (once everything was printed) was dig in the action camera box for some bits and sling the lot together.

I decided not to use foam pads for the mirror bracket, this time going for a proper 2 part adhesive from Araldite. This will provide a much stronger bond and only requires a small area to be sanded to hep key in the powerful glue.

|

| Finally sorted |

Rear view camera.

The back end of the van is pretty plain, not really giving you anywhere suitable for a reversing camera to mount to. There are a few places this camera can mount to around the licence plate but this will be too low down for my liking then you are basically left with the top of the van as the next option which is super high.

To compound this, with all of the interior modifications, there is no easy way of tracking the wiring from the front to the back.

With this in mind I decided to get the above done first and left the camera till later probably when I had to do something else which would give me some access that I otherwise wouldn't have.

A further check showed that the kit reversing camera's wiring was too short for the van anyway so I went shopping for a van specific camera.

Another camera was bought: this one was designed to be mounted on top of a van, had a powerful ir light source and a nice long cable. I spotted it uses an RCA outlet so bought an RCA to 2.5mm aux in adaptor so it would interface with the mirror.

It was a while till I got round to sorting the camera out as I had plenty of other things to be getting on with. Once I got round to it I took a trip up the ladder to see about roof mounting this thing. There is a bit of a gutter at the back of the Daily so no flat surface to mount to frustratingly. I figured I could mount it a bit deeper into the van and still get a good view behind me.

It was a while till I got round to sorting the camera out as I had plenty of other things to be getting on with. Once I got round to it I took a trip up the ladder to see about roof mounting this thing. There is a bit of a gutter at the back of the Daily so no flat surface to mount to frustratingly. I figured I could mount it a bit deeper into the van and still get a good view behind me.

The area of the roof was cleaned and any rust spots I found were cleaned up and repainted.

Once I had checked and rechecked where I wanted the camera to go I drilled the two mounting holes and an 18mm hole for the grommet. This got me to the false top of the roof where I could then chase the cable to the side and forward, in theory.

After a bit of faffing running string through any holes I could find to pull cable through it dawned on me that I hadn't actually tested this camera on the mirror screen yet. The idea had skipped my mind as it had been so long since I started this job.

After a bit of faffing running string through any holes I could find to pull cable through it dawned on me that I hadn't actually tested this camera on the mirror screen yet. The idea had skipped my mind as it had been so long since I started this job.

I grabbed the camera and adaptor cable and ran them to the mirror; nothing. Balls.

I tried the original camera in the mirror and that worked as it should. I then tried the new camera on the TV which worked as well. What was this things problem?

Something was up with the adaptor.

I tried trimming the rubber to see if it was restricting it being inserted in the plug hole. Not that.

I then cut the whole thing open but the one wire was soldered to the correct pole.

I then wondered if the lack of earth was causing some kind of upset but bridging that in made no difference either. Beaten, I gave in for the day, plugged up all of the holes I had made and left it for another time.

A further check showed that the kit reversing camera's wiring was too short for the van anyway so I went shopping for a van specific camera.

Another camera was bought: this one was designed to be mounted on top of a van, had a powerful ir light source and a nice long cable. I spotted it uses an RCA outlet so bought an RCA to 2.5mm aux in adaptor so it would interface with the mirror.

It was a while till I got round to sorting the camera out as I had plenty of other things to be getting on with. Once I got round to it I took a trip up the ladder to see about roof mounting this thing. There is a bit of a gutter at the back of the Daily so no flat surface to mount to frustratingly. I figured I could mount it a bit deeper into the van and still get a good view behind me.

It was a while till I got round to sorting the camera out as I had plenty of other things to be getting on with. Once I got round to it I took a trip up the ladder to see about roof mounting this thing. There is a bit of a gutter at the back of the Daily so no flat surface to mount to frustratingly. I figured I could mount it a bit deeper into the van and still get a good view behind me. The area of the roof was cleaned and any rust spots I found were cleaned up and repainted.

Once I had checked and rechecked where I wanted the camera to go I drilled the two mounting holes and an 18mm hole for the grommet. This got me to the false top of the roof where I could then chase the cable to the side and forward, in theory.

After a bit of faffing running string through any holes I could find to pull cable through it dawned on me that I hadn't actually tested this camera on the mirror screen yet. The idea had skipped my mind as it had been so long since I started this job.

After a bit of faffing running string through any holes I could find to pull cable through it dawned on me that I hadn't actually tested this camera on the mirror screen yet. The idea had skipped my mind as it had been so long since I started this job.I grabbed the camera and adaptor cable and ran them to the mirror; nothing. Balls.

I tried the original camera in the mirror and that worked as it should. I then tried the new camera on the TV which worked as well. What was this things problem?

Something was up with the adaptor.

I tried trimming the rubber to see if it was restricting it being inserted in the plug hole. Not that.

I then cut the whole thing open but the one wire was soldered to the correct pole.

I then wondered if the lack of earth was causing some kind of upset but bridging that in made no difference either. Beaten, I gave in for the day, plugged up all of the holes I had made and left it for another time.

Comments

Post a Comment